Similar Posts

The Versatility of Ceiling Aluminum Profiles: A Modern Architectural Solution

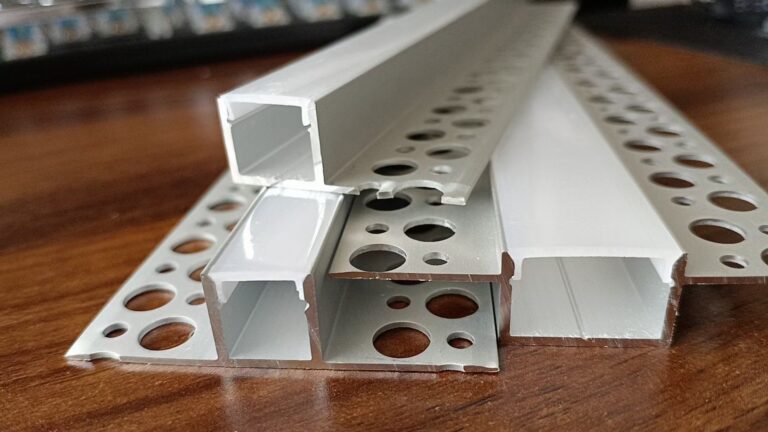

Home Transform your home into works of art with our ceiling aluminum profiles In the domain of contemporary architecture and interior design, ceiling aluminum profiles have emerged as a preferred selection among designers and builders. These sleek and functional profiles provide a multitude of advantages, seamlessly integrating aesthetics with practicality. Let us delve into the…

What’s Our Hot Selling Lace Embedded Aluminum Profile ?

Home Due to the needs of modern decoration and lighting, more and more pre-embedded lace profiles have become popular, because they can be hidden inside the gypsum board, and there is only a line of light when the light is on. Many customers will choose lace pre-embedded profiles. But with different sizes and different places…

How’s the floor profile look like after 2 years of installation?

Home Since road tread formations are subject to more pressure and friction than interior profiles, we have to use high quality products to meet the needs of the project. Top quality floor profile : Thickened aluminum and thickened cover By emphasizing the strength, durability, and design versatility of your aluminum floor profile series, this enhanced…

Why are LED aluminum profiles so important to us?

Home There are many places where lights are used in life, but the function of LED aluminum profiles is to decorate your home, your office, bring a different atmosphere, and also provide you with emotional value. The role of small LED aluminum profiles can help you a lot. LED aluminum profiles are important for a…

Why Choose Bending LED Profiles?

Home Bending LED profiles are a fantastic option for creating innovative lighting designs Design Freedom:Bending LED profiles open up new creative possibilities for lighting designers and architects. Unlike traditional rigid lighting fixtures, these flexible profiles can be shaped to follow the natural lines of a space. This allows for the creation of fluid, organic patterns…

Using Our Office Aluminum Profile for General Office and Workspace Areas

Home Featured Bendable Office Aluminum Profile -providing both illumination and a touch of elegance. Lighting plays a crucial role in creating a productive and comfortable office environment. The right lighting can improve focus, reduce eye strain, and promote employee well-being. A carefully designed office lighting profile considers multiple factors like brightness, color temperature, and fixture…